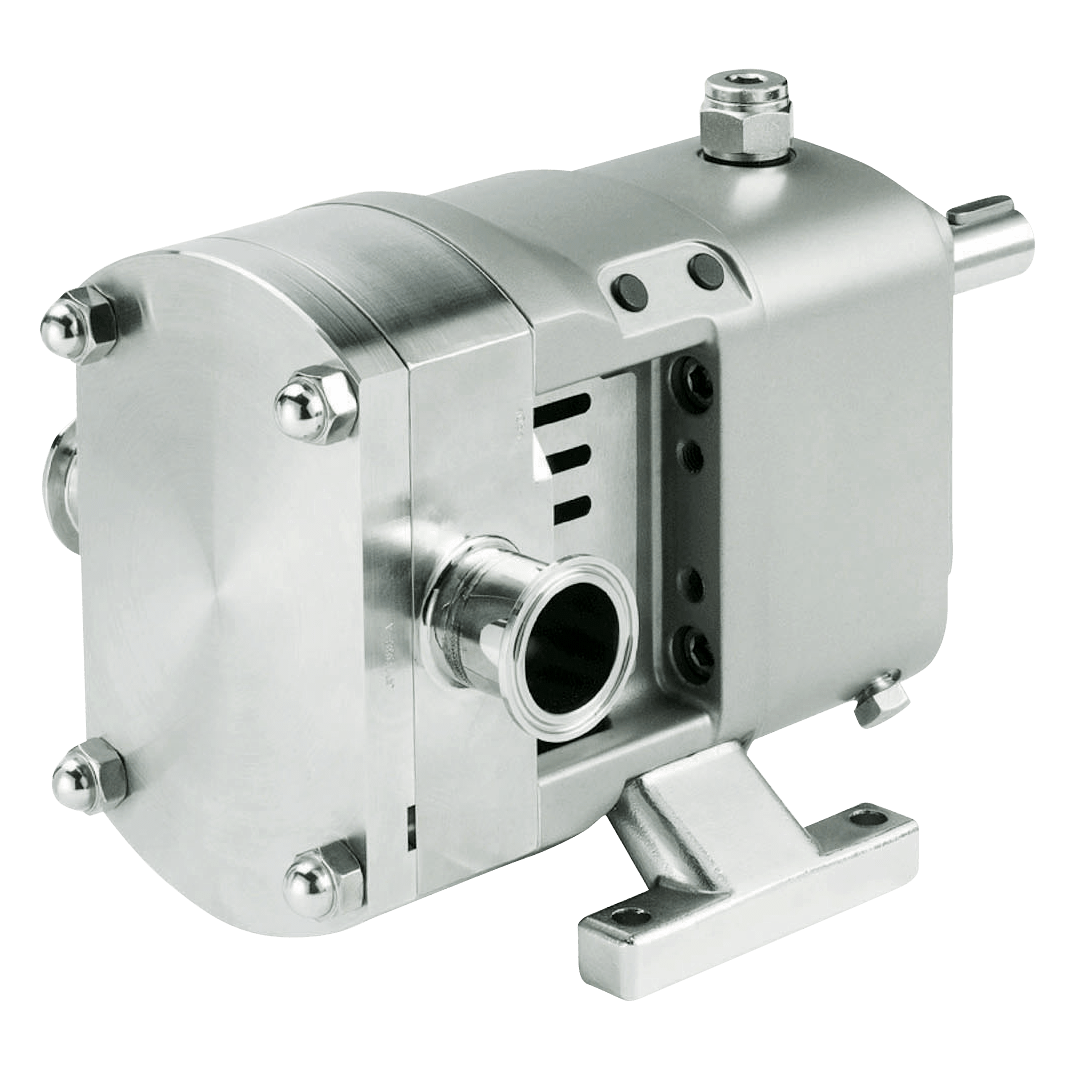

Classic+ Hygienic Rotary Lobe Pumps (3-A)

The Classic is a positive displacement rotary lobe pump designed using the latest innovative computer-aided techniques and manufactured to meet today’s stringent demands for high product quality, reliability, ease of maintenance, the economy in the purchase, and low lifetime costs.

VERSITILITY AND SAFETY: For maximum flexibility, the feet of the pump may be removed and re-set to change the drive and port orientation to operate with the ports in a horizontal or a vertical position or to accommodate a top or bottom shaft drive. For heat-sensitive applications, jackets may be fitted to the rotor case and/or front cover to either heat or cool the pump head. To protect the pump, a spring-operated relief valve may be fitted to the front cover. This can be set on-site to protect the pump from over pressurization and is available with air operation for automated CIP processes.

STAYS CLEANER: Hygienically designed, it combines a gentle pumping action for delicate liquids with soft solids as found in the food industry whilst robust, stainless steel construction is suited to the aggressive slurries and pastes of the chemical industry. For hygiene and corrosion resistance all product-wetted parts are manufactured from AISI 316L (DIN 1.4404) type stainless steel.

EASIER MAINTENANCE: The mechanical seals are of cartridge design with the rotary seat retention isolated from the pumped medium giving improved operation and easier assembly, setting, and maintenance. Available in single, flushed or double seal configurations, all seal combinations use the same component wearing parts.

Features:

Superb operator and maintenance features, giving real operator benefits:

- Classic rotary lobe pump design

- Stainless steel 316L (DIN1.4404) contact parts

- Used throughout the whole of the process industry

- ATEX compliant

- Tri-lobe or multi-lobe rotor forms

- Flush rotor retention

- Hygienic flush front cover design

- Universal mounting with bolt-on feet

- Easy to change shaft and port orientation

- Self-draining when ports vertical.

- Low shear

- Externally mounted shaft seals

- Mechanical seals or simple ‘O’ ring seal

- Operates in either direction

- Standard 0.8μm Ra machine finish

- Enhanced surface finishes available

- Scratch-resistant powder-coated finish on CP10 – CP30

- The two-part epoxy finish on CP40 & CP50

- Protected front oil seals, prevents ingress of water from pressure washers

- Simpler to maintain